polandbr.feb22

|

Back to Chronicles Work Begins on Cambridge Junction Covered Bridge! Kick-off Meeting Held February 12 Tuesday, February 27 Monday, March 12 Wednesday, March 14 Friday, March 16 Monday, March 19 Monday, March 26 Wednesday, March 28 Saturday, March 31 Monday, April 2 Thursday, April 5 Friday, April 13 Friday, April 20

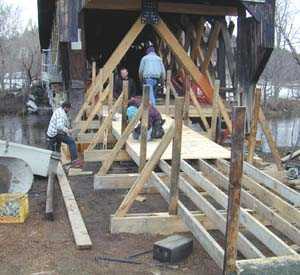

Cambridge, Vt. Thursday, February 22 - A lot has happened to the Cambridge

Junction Bridge since the kick-off meeting on February 12. Today there are three massive A-

frames standing inside of the structure; one at each portal and one at the center of the span. In

addition, two shattered diagonals (kingpost braces) have been replaced. |

The A-frame stabilizers

"And secondly, we took up the oak three-by-three running plank from the bridge floor. That took about eight thousand pounds of weight off the bridge. We're trying to take as much weight off as we can because of the condition of the bottom chords.

"The third thing we are going to do is put supplemental supports on the upper chords, both inside and outside. They are going to be three-by-tens, twenty foot long, and they'll be lag-bolted every ten inches with 3/4" x 7" lag- bolts and steel washers.

"The fourth thing we're going to do is put channel irons and one-inch rods connected together as a link. The rods will be tightened with 1300 pounds of torque, and that will stabilize the bottom chords. Those channels and rods are going top and bottom of the inside and the outside chord, so there will be four runs of those rods.

"At that point, we're going to have the north abutment and south abutment excavated to about four feet below road-grade level and remove all of the debris, and get down onto stone and concrete, or whatever we find is stable.

"From there we start a cribbing

process. The objective is to raise the bridge three feet to get it above ice-flow stage. And to

accomplish that we're going to use electrically operated hydraulic jacks. We're going to start with

very thin, what we call "pancake jacks" under each side of one of the abutments, and we're going

to jack the bridge up enough to get a substantial piece of oak under it. Then we'll reposition the

jacks to get about six inches. We'll go to the other end [of the bridge] and do the same process.

We're going to go up in six-inch increments from north end to south end, back and forth installing

blocking as we go so the bridge remains always stable, until we get our three-foot increase in

elevation.

"From there we start a cribbing

process. The objective is to raise the bridge three feet to get it above ice-flow stage. And to

accomplish that we're going to use electrically operated hydraulic jacks. We're going to start with

very thin, what we call "pancake jacks" under each side of one of the abutments, and we're going

to jack the bridge up enough to get a substantial piece of oak under it. Then we'll reposition the

jacks to get about six inches. We'll go to the other end [of the bridge] and do the same process.

We're going to go up in six-inch increments from north end to south end, back and forth installing

blocking as we go so the bridge remains always stable, until we get our three-foot increase in

elevation."This is all designed by John Weaver Of the Vermont Agency of Transportation. That will pretty much conclude our contract, except for the approach ramp which will be ADA acceptable and accessible to wheelchairs, and then the bridge will be turned back over to pedestrian traffic.

"The second phase will involve the complete rebuilding of the bridge. This is an interesting project, it's about an eight-week project and we hope to complete our phase before the ice goes out. We just need a lot of good luck, a lot of good days to work. If the weather stays cold we won't have work under the dripping of the eaves, so much of the work is working off of "Spider" stages that are suspended from the top chord while we put the supplemental chord re-enforcing on. If it stays cold we can [also] work from the ice and get the job done."

Alan Davis

Part of the stabilization work required that two broken truss members be replaced. Said Mr. Daniels: "We replaced two diagonals, one on the west side, downstream, one on the east side upstream. Those are six-by-tens about twelve and a half foot long. I believe back in the middle nineties somebody hit the bridge halfway through, right near the kingposts at the center and the bridge did receive extensive damage with the interruption of the load [distribution] on those members. That was one of the first things that we did. Took about one day to jack the bridge on the ice, we spread some drillage on the ice, set a hydraulic jack on a post. We got enough relief to get the old [diagonals] out and a little more to get the new ones in, so they are under [compression] now. The bridge still has negative camber, about a foot-and-a half." The ice was eighteen inches thick, he said.

Also hard at work was foreman Alan Davis, assembling the complicated "Spider" staging that will be used when the steel channels and rods are installed on the outside of the bridge trusses.

Cambridge, Vt. Tuesday, February 27 - With the three A-frames in place, the stabilization work has moved to the upstream upper chords.

Some of the upstream siding has been removed to gain access to the upper chords.

The upper chords being prepared for the installation of the longitudinal bracing and the hanging of the "Spider" staging

The "Spider" staging is assembled and ready for hanging from the upstream upper chord.

Cambridge, Vt. Monday, March 12 -

A portion of the bottom chord on the upstream side was found to have been damaged by ice some time in the past. The damaged area can be seen where the siding is cut away. All four chords, top and bottom of both trusses, are in the process of being braced in preparation for the lifting of the bridge.

"The fourth thing we're going to do is put channel irons and one-inch rods connected together as a link. The rods will be tightened with 1300 pounds of torque, and that will stabilize the bottom chords," said Anthony Daniels. The irons and rods can be seen here on the outside of the downstream bottom chord.

The spider staging is in position for work on the upper chord.

Cambridge, Vt. Wednesday, March 14 -

The north abutment and south abutments have been excavated to about four feet below road-grade level and the bedding for the chords has been exposed.

A view of the south-west corner of the bridge and exposed chord-end. It sits on a pad of hard-wood blocks atop the abutment bedding area.

Cambridge, Vt. Friday, March 16 -

Another view of the south-west corner of the bridge and exposed chord-end. The space for a pancake jack has been cleared. When the end-panel bracing is completed, the bridge will be ready for lifting.

Cambridge, Vt. Monday, March 19 -

The end-panels that extend past the Burr Arch at all four corners of the bridge need to be reenforced to enable them to support the weight of the bridge during the jacking operation. The reenforcing members under construction can be seen here in the south-east-end panels of the truss.

The joists running parallel to the bridge-floor will support exterior staging.

A detail view of the end-panel reenforcement structure. The timbers that slant downward toward the foreground sandwiching the kingpost braces will act as compression members. The reenforcement timbers slanting in the opposite direction will act as tension members.

Another view of the end-panel reenforcement construction. This work needs to be done at all four corners of the bridge before the jacking operation can begin.

Cambridge Junction, Monday, March 26 - "All of the additional bracing, the lattice bracing, will be done Tuesday, the 27th," said Raymond Hayes, Resident Engineer from the VTrans Construction Division. We're starting to jack on the south end to bring it up two inches.

"Wednesday we'll bring it up four inches and we'll go back and forth, two and four, because at no time can we go up more than two inches from one end to the other," Hayes said."The plan is to have it up and on blocks, two feet by Friday, and hopefully before this ice comes."

Watching the hydraulic controls and pressure gage for the "pancake" jack.

The "pancake" jack is seen here placed on the abutment under the chord-end at the south-east corner of the bridge. The jack will raise the bridge no more than two inches at a time, rotating from corner to corner.

Cambridge Junction, Wednesday, March 28 - The south end of the Poland Bridge has been raised two inches. Preparations are underway to lift the north end four inches. It is expected that the bridge will have been raised two feet by the weeks end.

"Butch" Simoneau is installing a tension rod in the end panel at the northeast corner of the bridge.

The chord-end at the northeast corner of the bridge is exposed and being made ready to receive the "pancake" jack.

Left to right - Phil Daniels and Brian Dube are installing the reenforcing timbers at the northwest corner end panels.

View of the Poland Bridge from the southeast end. Notice the scaffolding had been moved to facilitate the construction of the reenforcing timbers at the north end of the bridge.

The southeast chord-end sits on a two-inch stack of shims, the "pancake" jack rotated to another corner. When the bridge has been lifted high enough, the bridge-wrights will begin to insert cribbing timbers.

"It's up two inches, a half-inch at a time," says Brian Dube. The "pancake" jack has only a half-inch "throw," meaning that while the jack can lift a corner of this 140-foot bridge, its lifting distance is one-half inch. Then shims are inserted between the chord and the abutment and the jack is reseated to lift another half inch. The goal is an elevation of two feet.

Cambridge Junction, Saturday, March 31 - It's Saturday morning and Ray Hayes,

Alan Davis, and Brian Dube are on the job under a bright morning sun. Melt water is dripping off

the covered bridge roof-edge feeding a shallow pool on the ice below. The work is to continue

raising the bridge on its abutments toward the goal of four feet.

Said Resident Engineer Ray Hayes;

"This morning when we started they had it up twelve inches on the south end and thirteen inches

on the north end. They've got it up four inches today on the south end and we just finished four

inches on the north end. Next we'll go back south for another four there.

We'll get to twenty-five inches then we'll

put in the permanent block and jack it up another foot." (The permanent block referred to is a

cribbing of six-by-six timbers that will span and support both bottom chords at each end.)

Brian Dube is operating the hydraulic controls after Alan Davis set the pancake jack under the northwest corner of the bridge.

The northeast chord-end is resting on two stacks of six-by-six timber.

The northeast corner of the bridge viewed from the south bank of the river. The stack of six-by-six timber placed on the abutment can be seen from here. Notice the reinforcing timbers in the end panels of the truss.

Alan Davis is setting the pancake jack and placing steel-plate shims under the northeast corner.

Inside view of what is happening in the photo above. Notice the steel shims on top of the inside stack of timbers. The bridge is rising on the jack leaving a space on the front stack that will be filled with a two-by-six timber shim.

The yellow cylinder on the hydraulic tubing in the center of the photo is the 4-3/4-inch pancake jack that just lifted the corner of the bridge.

When the space under chords became high enough the 2-1/2" pancake jack was set aside and the 4-3/4" jack was used, explained Alan Davis. This jack has a 2-1/2" throw, moving the job along more quickly. They will soon be using a 14" jack which can lift up to a distance of eight inches. According to VTrans, the estimated weight of the bridge is 179,000 pounds, he said. That is approximately 89.5 Tons. These jacks, inserted under one corner of the bridge at a time, are lifting about 22 Tons.

Cambridge, Vt. Monday, April 2 - The south end of the bridge has been raised 26 inches off the top of the abutment on temporary timbers. The construction crew is preparing to build the "permanent" cribbing that will support the bridge during the second phase of the planned preservation. The cribbing will be constructed of 12" x !4" timbers. When this is complete the bridge will be raised to a final height of 3 feet, two inches, Alan Davis said.

The south end of the bridge is excavated and prepared for the construction of the "permanent " cribbing.

Phil Daniels prepares the 12" x !4" cribbing timbers.

Cambridge, Vt. Thursday, April 5 - Braced, reinforced, and standing three feet higher over the Lamoille River, the race to stabilize George Washington Holmes' covered bridge before this spring's high water has been won. The Stabilization phase of the work is nearly complete. Left to do is the construction of the ramps at each end and the installation of temporary siding to protect the trusses until the renovation phase begins.

The Poland Bridge at Cambridge Junction stands on its new

cribbing three feet higher over the Lamoille River than it did February 12 when the Stabilization

work began.

→

The Poland Bridge at Cambridge Junction stands on its new

cribbing three feet higher over the Lamoille River than it did February 12 when the Stabilization

work began.

→ Alan Davis, Butch Simoneau, and Phil Daniels have reason to

smile: they and the others on the Neal Daniels Construction team won the race to raise the bridge

the three feet believed necessary to lift the bridge above this spring's high water and ice floes.

→

Alan Davis, Butch Simoneau, and Phil Daniels have reason to

smile: they and the others on the Neal Daniels Construction team won the race to raise the bridge

the three feet believed necessary to lift the bridge above this spring's high water and ice floes.

→Cambridge, Vt. Friday, April 13 - The Daniels Construction team is finishing up the

last items in the contract for the first phase of the Poland Bridge preservation project; the entry

ramps and temporary siding to protect the truss from the weather during the interval between

contracts.

This week they are building the ramps

that will serve pedestrians and cyclists until the second phase of the project is begun, that of

restoring the structure of the bridge.

By mid-day Wednesday much of the south-end ramp was assembled in-place. The framing had been fabricated off-site and brought to the bridge by truck.

Friday the 13th and the ramp accessing the north end of the bridge is nearly complete.

A great deal of effort was spent in lifting the bridge three feet higher over the abutments to avoid the possibility of destruction by ice and flotsam carried by spring's high water. That scenario hasn't as yet occurred. The people on the bridge saw the ice melt and peacefully drift away. By Wednesday, April 11, the river was flowing quickly with just a scattering of floating ice. One of the larger chunks is shown here. Note the level of the river at the stones in the abutments, then view the next photo.

This photo was taken April 13 showing the river level to be approximately a half-foot higher than

in the photo above.

This photo was taken April 13 showing the river level to be approximately a half-foot higher than

in the photo above.According to the USGS Measuring Station in the Lamoille River at Johnson, about 8 miles upstream, the water conditions have been:

Apr. 12: flow = 2060 ft³/sec., stage = 6.08 ft.

Apr. 13: flow = 2930 ft³/sec., stage = 7.51 ft.

Apr. 14: flow = 2980 ft³/sec., stage = 7.59 ft.

Apr. 15: flow = 2770 ft³/sec., stage = 7.25 ft.

Flood stage at Johnson is: flow = 7220 ft³/sec., stage = 12.5 ft.

With a near-record snowfall this year we seem to be having a miraculously gentle melt-off to go with it so far.

Cambridge, Vt. Friday, April 20 - The pedestrian ramps are finished and the openings

in the bridge siding are closed temporarily against the weather with plywood and plastic sheeting.

This and with the bridge standing three feet higher over the abutments, the first phase of the two

phase project is complete.

The ramps will serve the public until the

structure restoration part of the project begins this coming fall. When the work on the bridge is

completed, the roadway will be restored and light motor traffic will permitted.

The Portals of the Poland Bridge are now served with railed

pedestrian ramps. The signs read: NO RECREATIONAL OR MOTOR VEHICLES ALLOWED

and PEDESTRIAN TRAFFIC ONLY BICYCLES MUST BE WALKED

→

The Portals of the Poland Bridge are now served with railed

pedestrian ramps. The signs read: NO RECREATIONAL OR MOTOR VEHICLES ALLOWED

and PEDESTRIAN TRAFFIC ONLY BICYCLES MUST BE WALKED

→ The old bridge is not very sightly right now, but the patches

will soon be replaced with new siding.

→

The old bridge is not very sightly right now, but the patches

will soon be replaced with new siding.

→ With the floor freshly swept and the interior suffused with

light admitted through the plastic sheeting, the bridge feels strangely snug.

→

With the floor freshly swept and the interior suffused with

light admitted through the plastic sheeting, the bridge feels strangely snug.

→return to top

Joe Nelson, P.O Box 267, Jericho, VT 05465-0267, jcnelson@together.net

Joe Nelson, P.O Box 267, Jericho, VT 05465-0267, jcnelson@together.net

No part of this web site may be reproduced without the written permission of Joseph C.

Nelson

Text Copyright © 2001, Joseph C. Nelson

Photograph Copyright ©, 2001, Joseph C. Nelson

This file posted February 23, 2001, rev. April 23, 2001